The use of the element fluorine to modify active substances is an important tool in modern drug development. A team at Goethe University Frankfurt has now achieved an important “first” by successfully fluorinating a natural antibiotic via targeted bioengineering. With this method, an entire substance class of medically relevant natural products can be modified. The method has enormous potential for the manufacture of new antibiotics against resistant bacterial pathogens and for the (further) development of other drugs. The startup kez.biosolutions GmbH will bring these research results to the application stage (Nature Chemistry, DOI 10.1038/s41557-022-00996-z).

Active drug agents have been chemically modified with fluorine for decades, owing to its numerous therapeutic effects: Fluorine can strengthen the bonding of the active agent to the target molecule, make it more accessible to the body, and altering the time it spends in the body. Nearly half of the small-molecule drugs (molecules up to approx. 100 atoms) currently approved by the U.S. Food and Drug Administration (FDA) contain at least one chemically bound fluorine atom. These include such different drugs as cholesterol-lowering agents, antidepressants, anticancer agents and antibiotics.

Bacteria and fungi often manufacture complex natural compounds to obtain a growth advantage. One possible route for the development of drugs from natural compounds is to modify these substances by adding one or more fluorine atoms. In the case of the antibiotic erythromycin, for example, the attached fluorine atom confers important advantages. The new erythromycin manufactured via this process can be accessed more easily by the body and is more effective against pathogenic microorganisms that have developed resistance to this antibiotic. However, the synthetic-chemical methods for inserting fluorine into natural substances are very complicated. Owing to the chemical and reaction conditions that are necessary, these methods are frequently „brutal,“ says Martin Grininger, Professor for Organic Chemistry and Chemical Biology at Goethe University. „This means, for example, that we are very limited in selecting the positions where the fluorine atom can be attached,“ he adds.

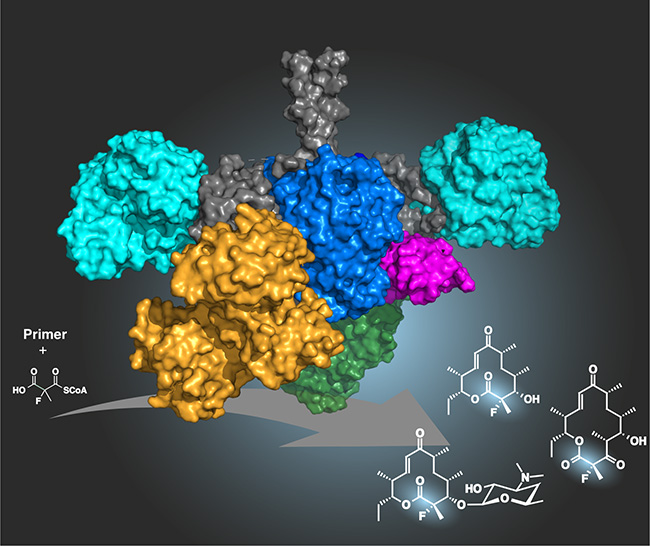

A German-U.S. scientific team headed by Prof. Martin Grininger and Prof. David Sherman, Professor of Chemistry at the University of Michigan, has now succeeded in utilizing the biosynthesis of an antibiotic-producing bacteria. In this process, the fluorine atom is incorporated as part of a small substrate during the biological synthesis of a macrolide antibiotic. “We introduce the fluorinated unit during the natural manufacturing process, an approach that is both effective and elegant,“ stresses Grininger, „This gives us great flexibility when positioning the fluorine in the natural substance – and allows us to influence its efficacy.“

To this end the project leaders Dr. Alexander Rittner and Dr. Mirko Joppe – both members of Grininger’s research group in Frankfurt – inserted a subunit of an enzyme called fatty acid synthase into the bacterial protein. The enzyme is naturally involved in the biosynthesis of fats and fatty acids in mice. The fatty acid synthase is not very selective in processing the precursors, which are also important for the manufacture of antibiotics in bacteria, Rittner explains. With an intelligent product design, the team succeeded in integrating a subunit of the murine enzyme into the corresponding biosynthetic process for the antibiotic. „The exciting part is that, with erythromycin, we were able to fluorinate a representative of a gigantic substance class, the so-called polyketides,“ says Rittner. “There are about 10,000 known polyketides, many of which are used as natural medicines –for example, as antibiotics, immunosuppressives or cancer drugs. Our new method thus possesses a huge potential for the chemical optimization of this group of natural substances – in the antibiotics primarily to overcome antibiotic resistance.“ To exploit this potential, Dr. Alexander Rittner founded the startup kez.biosolutions GmbH.

Prof. Martin Grininger has been conducting research on the tailor-made biosynthesis of polyketides for several years. „Our success in fluorinating macrolide antibiotics is a breakthrough we worked hard to achieve and of which I am now very proud” he says. “This success is also an impetus for the future. We are already testing the antibiotic effect of various fluorinated erythromycin compounds and additional fluorinated polyketides. We intend to expand this new technology to include additional fluorine motifs in collaboration with Prof. David Sherman and his team at the University of Michigan in the U.S.”

The search for drugs that overcome antibiotic resistance is a long-term task: depending on how frequently they are used, all antibiotics naturally cause resistances sooner or later. Against this background Dr. Mirko Joppe also believes that his work has broader implications for society. „Research on antibiotics is not economically lucrative for various reasons. It is therefore the task of the universities to close this gap by developing new antibiotics in cooperation with pharmaceutical companies,“ he explains. „Our technology can be used to generate new antibiotics simply and quickly and now offers ideal contact points for projects with industrial partners.“

The research work on polyketides described above was supported by the Volkswagen Foundation (within the framework of a Lichtenberg Professorship), the LOEWE MegaSyn research initiative funded by the Hessian Ministry for Science and the Arts, and the National Institute of Health in the U.S

Publication: Alexander Rittner, Mirko Joppe, Jennifer J. Schmidt, Lara Maria Mayer, Simon Reiners, Elia Heid, Dietmar Herzberg, David H. Sherman, Martin Grininger: Chemoenzymatic synthesis of fluorinated polyketides. Nature Chemistry (2022) https://www.nature.com/articles/s41557-022-00996-z